Proving the concept:

Weekday x unspun Body Scan Jeans

Setting a new standard for clothes shopping

Given a choice between off the shelf clothing made in sizes and on-demand clothing made in your size, what would you choose? This was the basic question that motivated our partnership with the denim enthusiasts at Weekday. We brought the concept of custom-fit clothing to the public to find out.

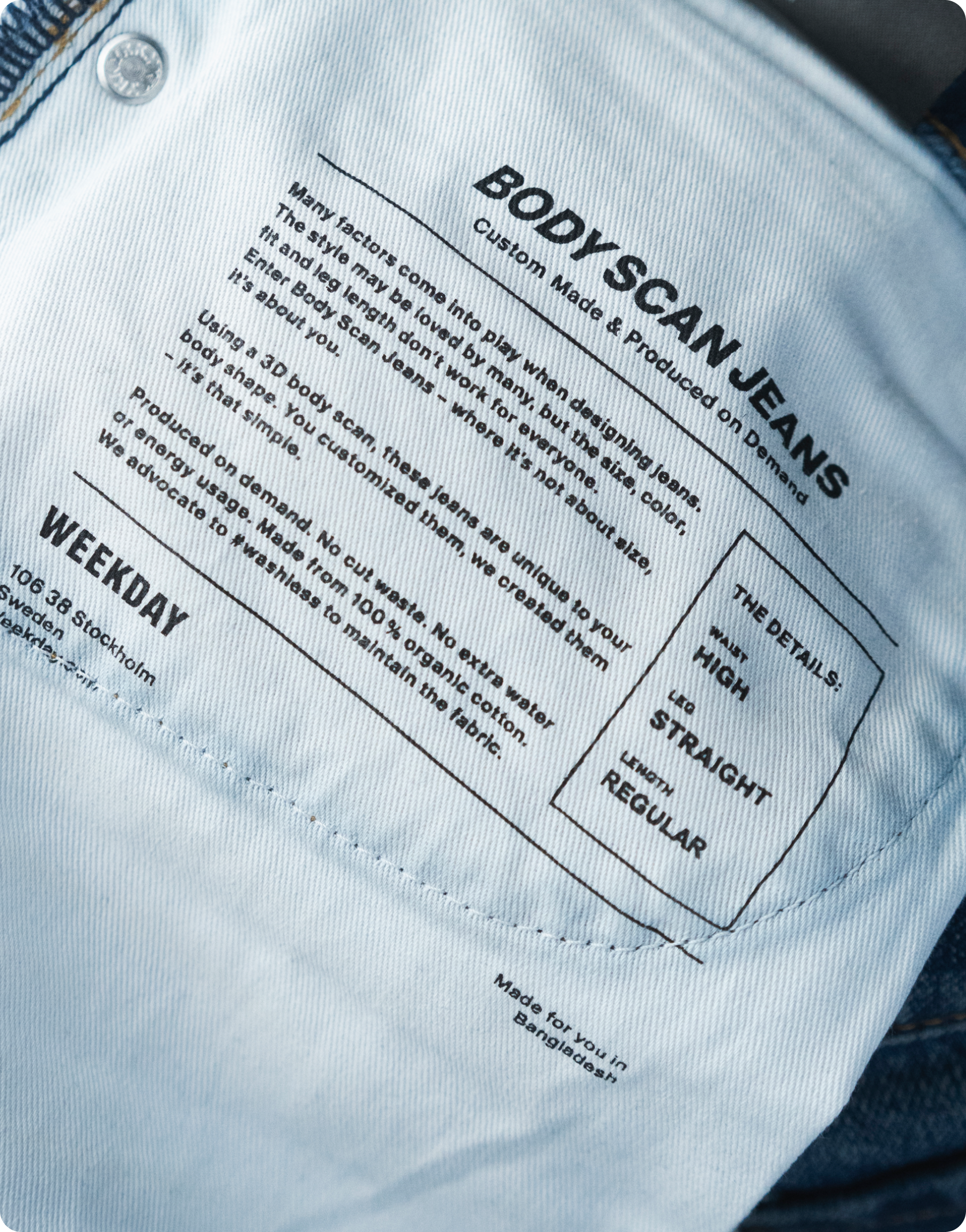

In between a personal shopper and a tailoring service, Body Scan Jeans proposed a new type of retail altogether. Using tech to fit apparel before making it, we aimed to give the customer a better product at a competitive speed and price.

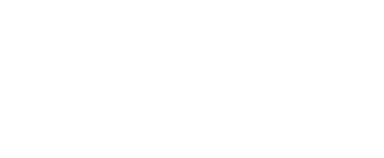

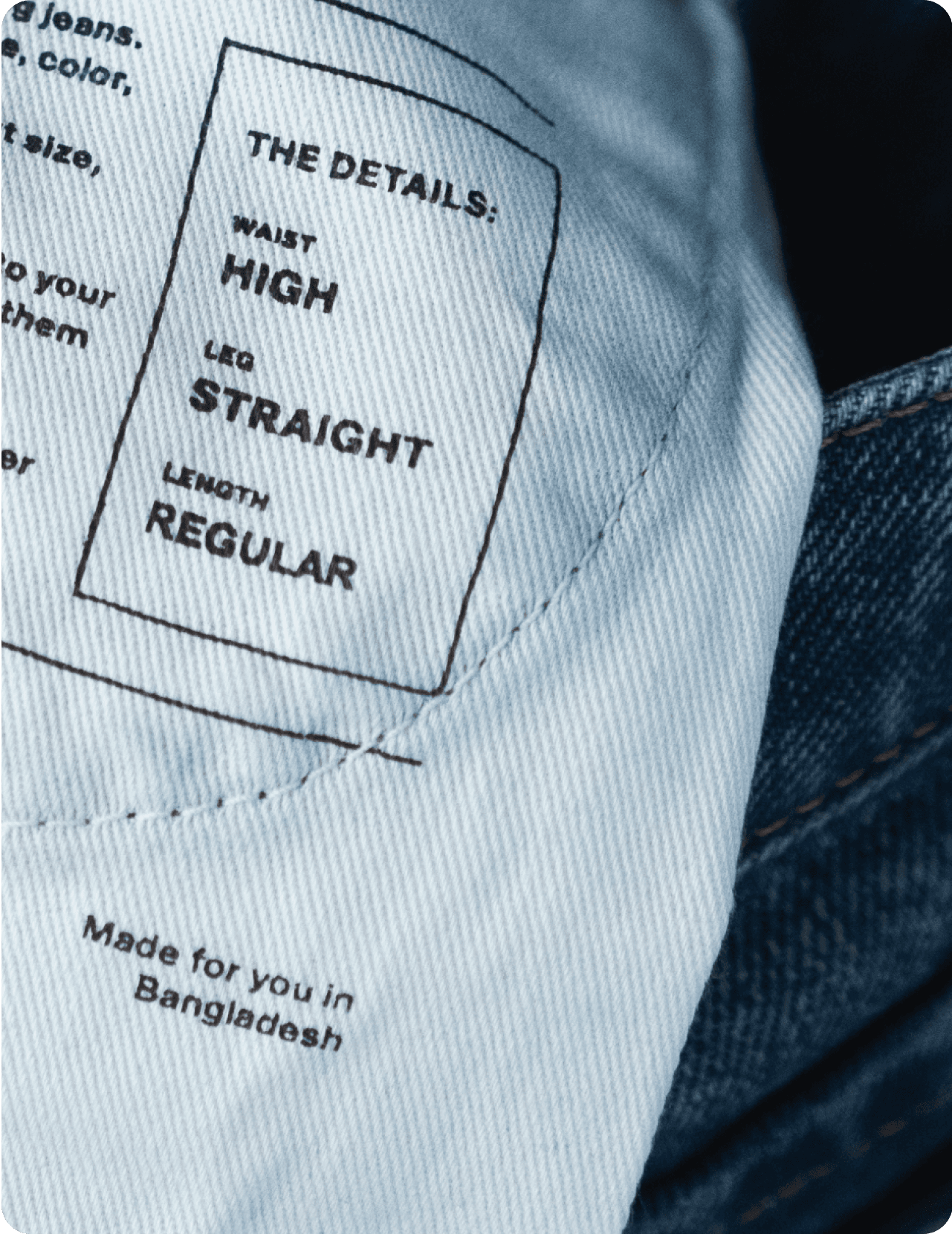

The experience was interactive. Instead of trying on jeans in the store, a customer took a body scan. Based on that scan, our Customizer tool displayed a digital mannequin approximating their figure. Manipulating a touchscreen, the customer saw how jeans in different cuts with various fabrics, rises, and lengths looked on the mannequin, and chose their preferred selections. Our fit algorithms calculated how to fit those selections according to their actual dimensions. From those calculations, Weekday manufactured the customer’s jeans and delivered them in two weeks.

Body Scan Jeans ran continuously in Weekday’s Stockholm flagship store from the Fall of 2020 to the Spring of 2022. While modeling how to gamify custom-fit clothing for the customer, the project demonstrated that even larger brands can execute an on-demand business model. Retail, retold.

Weekday makes popular streetwear for a diverse customer base, and unspun fits clothing to the diverse bodies of customers, to enrich the retail experience.

Broad appeal and extensive customization engenders more accessible apparel.

Weekday

Where the urban landscape and fashion meet, Weekday is there to curate it. Founded as a denim outfitter in a small store outside of Stockholm in 2002, within several years of operation the brand had joined the H&M Group as a purveyor of savvy yet understated staples. Weekday has cultivated its popularity among European youth by keeping a finger on the pulse of ever-evolving trends. By aligning with H&M’s broader sustainability goals, it has also prioritized modernizing its production. Making clothes from low-impact materials, decarbonizing factories, and conserving or recycling water are some of the ways Weekday seeks to usher in a net-zero future at scale.

What our partnership shows

Custom-fit clothing can be incorporated into the mass market

Clothing sized to the customer can be sold in addition to, rather than instead of, clothing in standard sizes. By lowering the cost of designing a bespoke garment, automated fitting technology brings down its retail price, expanding a brand’s market share to those unserved by sizes while retaining its target customer segment.

Customization of custom-fit clothes improves consumer choice

On-demand production is achievable at scale

We’ve built the tech, proved it works, and are ready to partner with the world’s most innovative brands.

Let's revolutionize fashion, together.

Learn more about our

Stories